Cannabis – #weed_be_good_together

Cannabis – #weed_be_good_together

Cannabis – #weed_be_good_together

A simple plant goes legal and wild goes the crowd! It is facinating to see all the activities in this old and black, now more and more legalized markets for Cannabis based products. The language in this industry is straight, enthusiastic and “sorry for my German” freakin cool. Social Medias like Instagram are the prime source to learn about the latest developements in the market. For manufacturers it is one of the most honest and fastest resource to get uncensored feedback about product, performance, quality, service, delivery times – anything, that makes your customer happy “or NOT”. Quick statements replace testimonials and thank God, the information seems not to be filtered at all.

What is it about Cannabis, that causes so much attraction.

Medical users: Researchers have found that Cannabinoids, the active chemical ingredients of the cannabis plant, have very similar effects to every human`s natural endocannabionoid system. They “use” the same neurons and receptors to pass messages between the brain and parts of the human body. Knowing this, a (partially) defect human endocannabionoid system can be supported with messages via cannabinoids. As of today, most of the research has been concentrated on 2 of approximately 100 Cannabinoids only: CBD (cannabidiol) and THC (delta-9-tetrahydrocannabinol). The medical effects sound promissing as CBD and/or THC have been tested positive to cure or help: pain sensations, mood and memory settings, appetite stimulation for HIV/AIDS patients, genetic brain disorders, Crohn´s diseases, ulcerative colitis, Parkinson`s disease, post-traumatic stress disorder, insomnia, inflammation, pain, amm. Scientists see a potentail to cure from some cancer types and the science is ongoing. Like any drug, occasional or well set individual doses will have hardly any negative impact and to much of consumption is to much.

Happy users: Legalization has a great impact on the daily consum. Drug stores offer Cannabis products of all sorts. More and more consumers don´t have to use illegal channels to “fly away, to better land” meaning to enjoy great feelings or just profit from pain relief. Of course Cannabis is a drug that helps to make “high” and it shall not be hidden, that some consumers and doctors have reported cases where paranoia or anxiety was caused by extensive use of THC.

Business opportunities: State by state, country by country – Legalization allows easier control and offers great tax opportunities for the Governments. The ongoing legalization of Cannabis has other massive effects. One of these effects is a new, now legal industry with hundreds or thousands of start up companies. The employment rate profits and (wo)man, you do feel that gold digger mentality in so many areas:

Farmers and start ups: The plant itself seems robust and grows nicely in warm ambients. It is a great alternative to farmers especially as they have always been full of ideas of what to make with the plants they grow. The variaty of products, flavors and consumer equipment is massive and it seems new stuff shows up daily on the market places. It is obvious however, that many of the small start up are desperate to find advise from trustful partners about how to generate profits from processing weed. Which are the methods and the equipment that bring the best results? Which brand(s) of manufacturers can I trust?

Equipment Manufacturers and Consultants: Similar to the regulated and structured Pharmaindustry the goals in the Cannabis industry are cost savings by minimizing time and optimizing yields (“minimize the bullshit let overs“). In this industry the influencers play their job pretty well and use social media channels big times. A common characterization of these pioneers is curiosity and their pure passion to optimize the production processes. They try, test and report about successes and Their opinions counts – often you find them sharing their knowledge in form of consultancies and they come from varied backgrounds. Some have have found their place to help farmers how to grow and process the plants. Others help new set-ups to produce CBC or THC. Others provide technical solutions and offer self manufactured or designed products (see typical applications below )

Equipment Manufacturers and Consultants: Similar to the regulated and structured Pharmaindustry the goals in the Cannabis industry are cost savings by minimizing time and optimizing yields (“minimize the bullshit let overs“). In this industry the influencers play their job pretty well and use social media channels big times. A common characterization of these pioneers is curiosity and their pure passion to optimize the production processes. They try, test and report about successes and Their opinions counts – often you find them sharing their knowledge in form of consultancies and they come from varied backgrounds. Some have have found their place to help farmers how to grow and process the plants. Others help new set-ups to produce CBC or THC. Others provide technical solutions and offer self manufactured or designed products (see typical applications below )

Big players: Is it diversified industry with many small and medium sized players only? No, global players in the Pharma and/or the Beverege businesses have recognized the chances for business expansion with new products that face hardly any concern from their consumers. Alcoholic drinks have found a maximum on consumptions. CBD mixed drinks may now find new and more attraction for consumers, so better be ready.

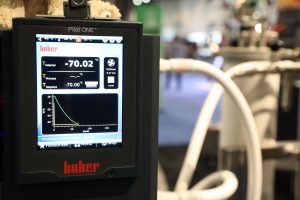

#MJBIZZ #Legendary_Unistat #set_temp_and_relax #Yeah_right #follow_the_crown

Show Time & Partnership in Las Vegas:

At the MjBiz in Las Vegas, we have met some mind setters. Boris Kogon@Bizzybee, Robert Gather@DabGenius, Jackie McGrane@shattergurljacqueline Guru`s in this industries with 40K plus followers in social medias. Like in any other industry our innovative and sustainable products are useless without being connected to an application where heat must be removed or added at variable temperatures. We have invited AGI, Bizzybeestbuilder, Cascade Botanical, ExtractionTec, Precision Extraction to present their latest products which

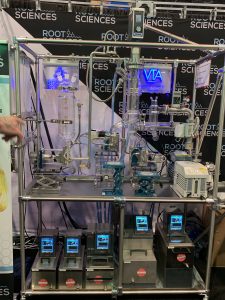

they demonstrated and explained to all visitors to our stand…. it takes two to tango! All Players had their own stands, too. Thankfully they had all tested HUBER temperature control products prior to the show and due to outperforming results they recommended to use our products in combination with their application solutions to the visitors. RootScience (VTA) has displayed their short path destillation racks combined with HUBER temperature control equipment on their own stand. Anyway….. #Weed_be_good_together

Distillation and Extraction methods in the Cannabis Industry

Short Path and Thin Film Distillation

Destillation is a classic way to separate thermal sensitive compounds. Organic substances, e.g. vitamins, flavoring agents or pharmaceutical intermediates may easily get damaged due to temperature stress (to low or to high temperatures), e.g. thermal decomposition, polymerization and other side reactions which may damage or have a negative influence on the final quality of the product. Thin film evaporation differentiates between thin-film, short-path or molecular distillation set ups.

In a Thin Film (Wiped-Film) Evaporator the product falls down through a heated cylindrical surface onto a cylindrical pipe. The liquid film is continuously mixed by a rotating wiper system. Evaporation via a Thin Film Distillation System eliminates the influence of the static height of liquid. Condensation takes place in a condenser located outside, which is connected to a vacuum system. The obtainable vacuum is limited to some mbar due to the pressure drop of the connection between evaporator and condenser.

The Short Path Distillation (molecular distillation*) is a real low pressure distillation method (pressures are as low as 0,001 mbar) and it allows individual settings for evaporation and condensation temperatures. The minimized operating pressure allows to reduce the thermal stress which results in a gentle distillation of the desired product. Short path distillation is a thermal separation method of high molecular and high-boiling products at high yields and good product quality. The condenser is located inside a cylindrical evaporator and the distance for the vapors between evaporator and condenser is designed to be extremely short, so that there is hardly any pressure drop at all. Once the distance between evaporator and condenser is in the order of the average free path length of the molecules, the process is called “Molecular Distillation“.

The purpose of CBD extraction is to create a highly concentrated form of cannabinoids (and others ingredients) to make it suitable for human consumption. Special cannabis strains or hemps which contain rich amounts of CBD are the preffered option for extraction methods. There are however serveral methods to extract Cannabinoids:

CO2 Extraction

CO2 extraction is a solvent based extraction method. Pressurized carbon dioxide (CO2) pulls CBD (and other phytochemicals) from the plant. CO2 acts as the solvent which extracts the cannabinoids at certain temperatures and pressures. It is known as a safe and effective method, however it involves high quality equipment which has its value and price. Sophisticated machines work to freeze the CO2 gas and compress it into a supercritical cold liquid state. The method is divided into supercritical, subcritical and ‘mid-critical’ categories whereby supercritical is the most popular form of CBD extraction as it is safe and provides products with high purities. CO2 typically behaves like a gas at standard pressure and temperature, and is easily changed to a solid (dry ice) while in this state.

Suitable temperature control and/or pressure control equipment may then turn CO2 gas into a liquid by ensuring the temperature drops below -69 degrees Fahrenheit while increasing the pressure to over 75 pounds per square inch (psi). This is the actual starting point for CO2 Cannabis extraction. CO2 in the liquid form becomes supercritical by increasing both temperature and/or pressure. Supercritical means the CO2 is now capable of adopting properties halfway between a gas and liquid simultaneously. Effectively, the supercritical CO2 is capable of filling a container (like gas) while also maintaining density (like a liquid). When CO2 is in its supercritical state, it is ideal for chemical extraction because it won’t cause the denaturing or damage that would make it unfit for human consumption.

Extracting the CBD oil using this technique starts with liquid CO2, raising its pressure and temperature by using a compressor and a heater. The next step involves passing the supercritical carbon dioxide through some high-quality cannabis which should be in an extractor. At this stage the CO2 will pull the essential trichomes and terpene oils out of the plant. The solution passes a separator and breaks down into its requisite parts. The “good stuff” (including trichomes and terpene) ends in a collection container. Meanwhile, the supercritical CO2 passes a condenser and turns back into a liquid. Finally, the liquid goes to a special storage tank and can be re-used for the next process batch.

Subcritical C02 extraction

This form of extraction involves low temperature and low pressure. Subcritical extractions take longer than their supercritical counterpart and also produce a smaller yield. While it retains the terpenes, essential oils and other sensitive materials, it doesn’t extract larger molecules such as chlorophyll, omega 3 & 6. Subcritical extraction is less likely to damage terpenes. Mid-critical is simply a general range between subcritical and supercritical. Some companies combine supercritical and subcritical to create a full-spectrum CO2 cannabis extract. They use the subcritical extraction method to separate the drawn out oil and draw out the very same plant material using supercritical pressure. The oils are then homogenized into one which creates a unanimated oil. Supercritical CO2, for its part, has been praised for its relative safety in terms of toxicity as well as environmental impact. That said, the lengthy purification process required to remove co-extracted constituents, such as waxes and plant fats, from the extracted product can take away from the final cannabinoid and terpenoid profile of extracts yielded during supercritical CO2 extraction.

Hydrocarbon Extractions

There is not THE perfect solvent for cannabis extraction in every way. Butane, the most common hydrocarbon solvent currently used in extraction is favored for its non-polarity, which allows the extractor to capture the desired cannabinoids and terpenes from cannabis without co-extracting undesirables including chlorophyll and plant metabolites. Butane’s low boiling point also makes it easy to purge from the concentrate at the end of the extraction process, leaving a relatively pure byproduct behind. Butane is highly combustible. Cheap butane extractors designed for home use have been responsible for multiple stories of explosions resulting in serious injuries and giving cannabis extraction as a whole a “bad rap”. Also, low-purity Butane utilized by unscrupulous extractors can retain an array of toxins that are harmful to humans. Propane and Butane both have low boiling points allowing the extraction of botanical oils without using high temperatures and high-pressures. Both high temperature and pressure have negative impacts as they degrade the end product. Propane Extractions and Butane Extractions allow for much faster run times than Ethanol or C02 extraction, causing less degradation in the process and resulting in a larger variety of end products. Butane Extraction is overall slower in comparison to Propane Extraction.

Ethanol extractions however, are considered to be effective, efficient, and safe to handle. Other advantages of Ethanol extractions are that storage limits are much more lenient allowing for more storage in the facility. Meeting fewer requirements allows the user to extract larger volumes of cannabis at once. Done properly, Ethanol extraction may eliminate the need for a dewax or winterization process. Last but not least Ethanol extraction is ideal to create the full spectrum of hemp extracts and tinctures. It is common understanding however, that Ethanol is not the solvent of choice when it comes to products like “shatter” or “sauce”.