Flow control and component testing

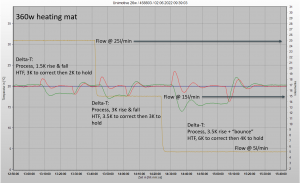

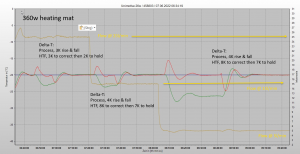

The Unimotive range of units are designed specifically to be operated using water/glycol (50/50 mix) as a heat transfer fluid (HTF) at component test temperatures down to -40°C. To demonstrate the ability of a “Unimotive 27w” coupled with a Flow Control Cube (FCC) equipped with an inductive flow sensor, we carried out a case study to mimic a test set-up using an aluminum cold plate and a 360w heating mat to simulate a component under test at 20°C and then -20°C with three different HTF flow rates at each test temperature. The intent was to demonstrate the maximum rise & fall of temperature and the time taken to regain the set-point on the test plate as a heat load of 360w is first applied and after stabilization, removed. The graphics show the resulting performance at both temperatures at flow rates of 25 l/min, 15 l/min and 5 l/min.

The featured image shows the Unimotive 27w coupled with 6 x MFCC‘s (Multi Flow Control Cubes), each one capable of providing different flow rates to the application from 1 x Unimotive unit.