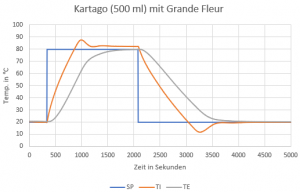

Grande Fleur controlling a PREMEX SOLUTIONS pressure reactor

This case study demonstrates the rapid and tight control over a PREMEX SOLUTIONS “Kartago”0.5-litre pressure reactor:

Heat Transfer Fluid (HTF): M20.195/235.20

Total HTF volume: Approx. 4 Liters

Reactor contents: 0.5 Liters of Water

Tubing: 2 x 1.5m (M16, #6085)

Stirrer speed: 165 rpm

Control mode: Process control

Setup: The reactor was connected to the Grande Fleur via 2 x M16 metal insulated tubes. Control was via a process based Pt100 connected directly to the Grande Fleur.

The installation and commissioning was carried out by Mr. Haron Sekkai of “HS Ingbuero” (info@ingbuero-hs.de)

Heat up from 20°C to 80°C took approximately. 20 min (Ramp-rate: 3K/min)

Cooling from 80°C auf 20°C approximately 30 min (Ramp rate: 2K/min)

“SP” = Set Point “TI” = HTF Temperature “TE” = Process Temperature