Temperature Control for botanical extraction, distillation and recovery (Weed be good together – part 2)

Temperature Control

Temperature Control

for botanical extraction, distillation and solvant recovery

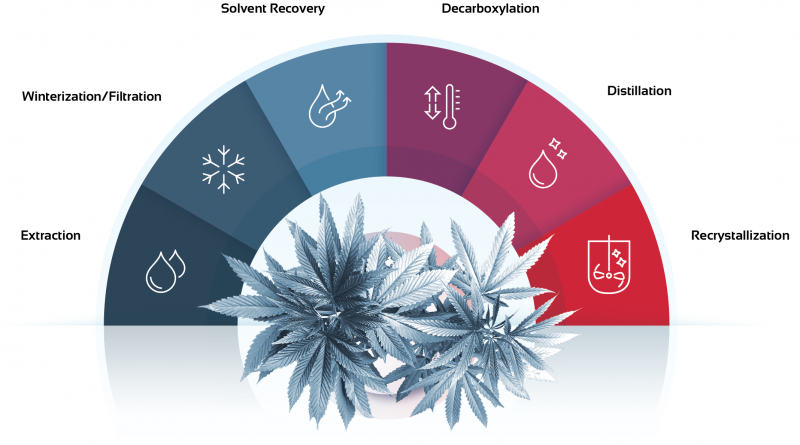

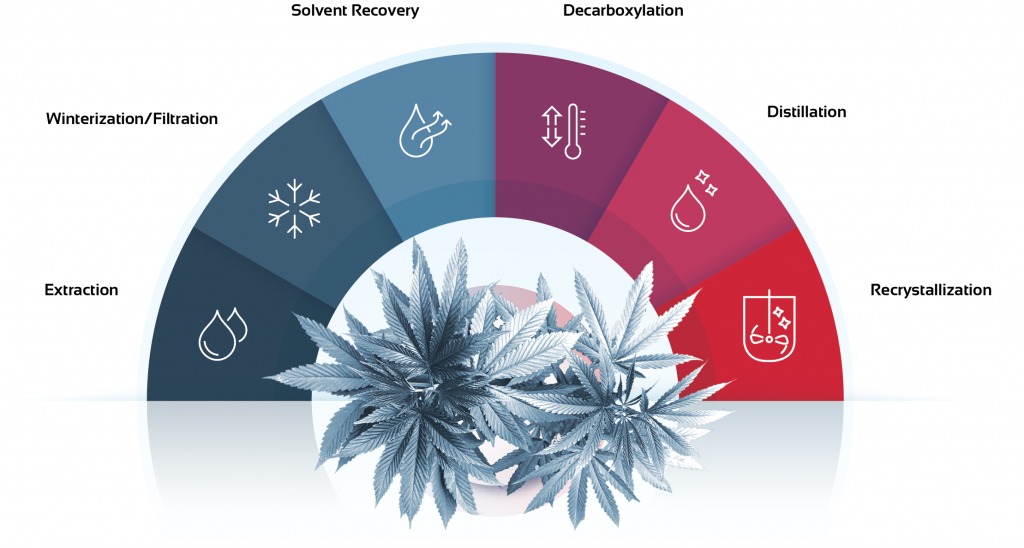

During the isolation and refinement process of CBD, or other cannabinoids, stable and accurate temperature control can aid in the reduction of process times, improvement in purity and yields. Increased process efficiency can lead to an increase of material purity; this will result in lower operating costs and a greater yield. As a result, this leads to a faster return on capital expenditure through increased process profits.

Reducing the time it takes to reach process critical temperature at which the next processing stage can be started, will increase the number of process runs achievable in a working day or a single shift.

Reliability is also a key factor when the pressure is on to meet timelines or to complete the chemistry and deliver an end product during a limited harvest window, or simply to meet costumer demands.

You can stand on the reliability and robustness of Huber units. There is no compromise in the quality of the engineering and materials used in the construction. It is a major reason why HUBER is the bench mark in performance and reliability/dependability of temperature control across many industries including Aerospace, Automotive, Semiconductor, Chemical and Pharmaceuticals.

From each stage in the process, the predictability of the resulting product, the volume and its concentrations will contribute significantly to the efficiencies of the subsequent processes. The volume and strength of the process material makes it easier for the subsequent formulation stages to produce a predictable ingredient for final product be it edibles, ointments, body lotion etc. When it comes to temperature control, it is not just about the cooling or heating power. If that power is stuck in the circulating bath, it is useless; the key to efficient and cost effective temperature CONTROL is in the efficiency of heat transfer. If the power is transferred efficiently, the process can be operated with a lower-powered, smaller circulator which costs less to buy and run. The heat transfer fluid (HTF) also has a big impact on the efficiency of the whole system. The HTF must be able to transfer heat energy from where it is useless (in the circulator or chiller) to where it is needed (e.g. the condenser coil, reactor jacket or thin film evaporator jacket etc.). To do this it must remain a liquid, with a low viscosity and density, while operating at the lowest and highest circulating temperature. This will maintain high flow rates and efficient thermal transfer.

Extraction – high volume production

There are many ways to do an initial extraction, but all these methods have one thing in common – Huber. Whether it be ethanol extraction or hydrocarbon, CO2 or propane, ice water or heptane, Huber TCUs play a vital role in the cooling of solvent and the regulation of extraction temperatures.

Hydrocarbon: For hydrocarbon extraction, operators often utilize Huber CC and Unistat series to cool down solvent tanks, material columns, and various components. The target temperature range is generally -40C to -80C. Huber heaters, such as the KISS 202 and CC-315B are often used on the solvent evaporation side of these closed loop systems.

Ethanol: In ethanol extraction, the Huber Unistat and CS-series are often used. Ethanol is generally brought down to temperature in a holding tank and then transferred to the process. Heat exchangers and flow through chillers can also allow for the cooling of ethanol. These applications generally call for large volumes to be cooled quickly, requiring a high cooling capacity in the -20C to -80C range.

Co2: In the CO2 extraction process temperature control plays a crucial role. Columns are heated and chilled, as are feed and solvent lines, all in order to ensure extraction temperatures as well as maintain solvent pressure and flow. The Unistat T305 heater & CS-chiller are often paired with these units.

Ice water: Huber Unichillers and CS-chillers are not commonly seen, but sometimes utilized in the process of making bubble hash. Jacketed tanks are chilled down to temperature, in order to increase efficiency and reduce resource consumption.

Professional Scale-up

With higher production goals comes larger equipment requirements; with the associated increase in cooling and heating powers. The Huber standard product range starts at cooling powers of 280 watts at 15°C up to 130kW at 15°C. Operation remains simple from the smallest to the largest.

Interfaces facilitate automation, monitoring and recording. Production demands are crucial and flexibility is a highly desirable option, especially with varying production demands. For this reason it is simple to run Huber machines in parallel as “redundant systems”. This also gives a dimension of security in always having spare capacity if needed in a hurry.

With powerful circulation pumps, high cooling & heating powers; Huber units can be integrated into high capacity production facilities production systems with daily target yields of circa 10,000 lbs/day (circa 4,5 kg/day). Standard products in the Huber range include units with cooling powers of 60kW at -40°C (Unistat 680w) and for ultra low temperature applications, up to 25 kW at -60°C (Unistat 950w) is available as. Process tanks and reactors with volumes as large as 2,000 litres can be cooled to these low temperatures without the need for liquid nitrogen.

Winterization

In order to remove undesirable fats and waxes, cannabis extracts are often suspended in solution and brought down in temperature. Holding the product at temperatures below -20°C in a jacketed vessel can be achieved by using either a Huber Unistat or a Huber “open bath” system. The benefit of a Unistat is that the temperature required to initiate the winterization process will be achieved much quicker than with an open bath unit and so increasing the number of batches processed per shift.

The most suitable unit will depend on the size of the processing vessel, time-to-temperature requirement and the target temperature.

Filtration

Advanced filtration often requires specific temperatures. Whether it be -80C to filter out fats and waxes , or +40C for bleaching clays, Huber has a solution.

Solvent Recovery

The life blood of any solvent recovery system is its chiller. Robust and reliable chillers eliminate breakthrough and maximize solvent recovery. Huber chillers are ideal for recovery systems such as rotary evaporators and falling films.

Solvent recovery generally calls for condenser temperatures of -10°C to 0°C, Huber CS chillers as well as Unichillers are frequently paired to these applications.

Decarboxylation

The temperature requirements at this stage of the process are typically between 90°C and 150°C. Huber heated circulators are often used to achieve these higher temperatures. ** balance **

Fractional Distillation

The wiped film evaporator (WFE) and short path distillation apparatus are the most common methods for refinement of crude oil. In this stage of purification, temperature stability & control are integral to process efficiency. Molecular distillation can take many forms, some more complex than others, but they all require heating and cooling in varying zones; at varying set points. To maximize automation, our pilot one system will allow all of the TCU’s to be controlled from a central point. Below are some examples of OEM pairings

Cascade Botanical

Cascade Botanical

“Purepath 100” Distillation System

• Minichiller 600

• TC45

• Ministat

• CC 304

• CC 202C

The picture shows a population of Huber units working to ensure the highest purity by providing perfect temperature control.

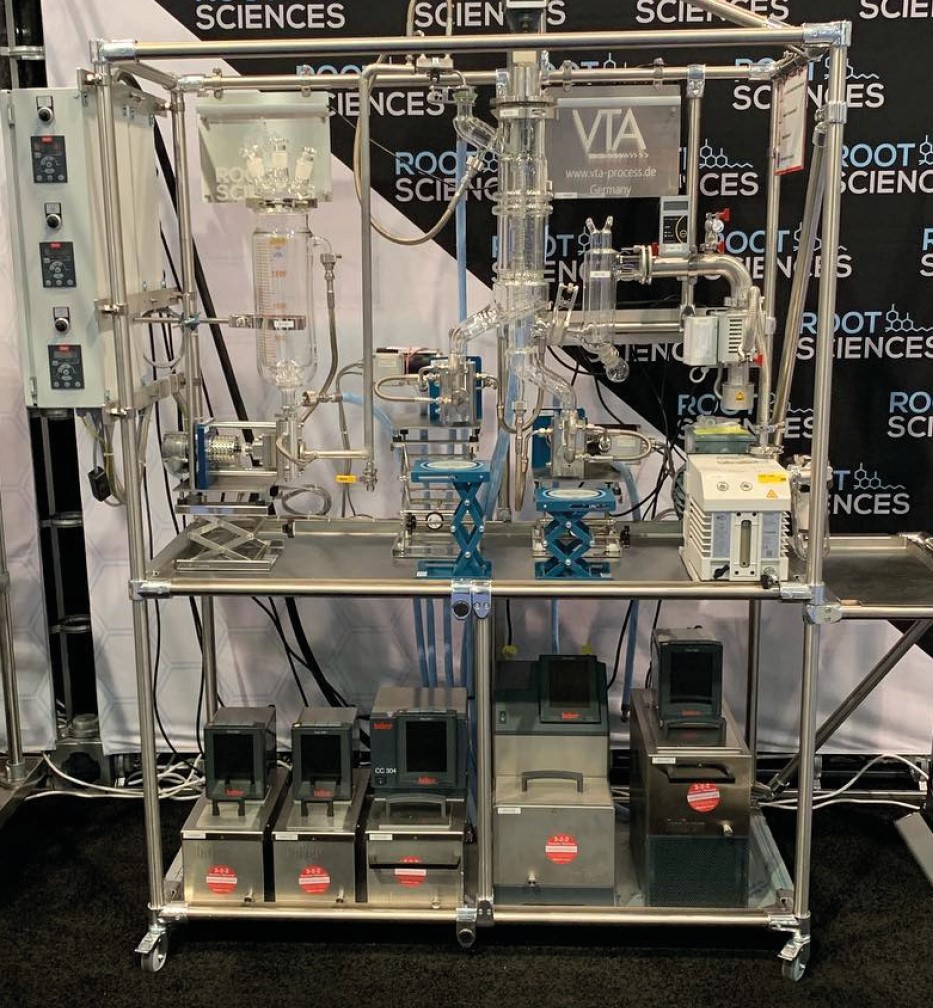

Rootscience

VKL 70-5 — Short Path Distillation

• CC-205B

• CC-308B

• Ministat

• CC K6

Here Is a KISS K-6 controlling the liebig of a still-pot style short path.

Bizzybee LLC

Bizzybee LLC

LARGE ETHYL SOLVENT RACK

Unistat 815

Precision Extraction Solution

X10 multi-solvent Extractor

Isolation;

The re-crystallization of cannabinoids is most commonly done within a jacketed reactor. In order to maximize productivity, precise and quick temperature control is essential. Automation is easily attainable with the PilotONE programmer allowing for custom cycles and temperature ramps to be created and if required, saved onto a USB thumb drive. With the Unistat series, isolate production has never been easier or more efficient. Operators most commonly use the CC-508,Unistat410, or Unistat 525 for these processes. —

Formulations & quality control:

In the final stages of processing, extracts are often blended or mixed into formulations. Whether to facilitate a reaction, aid in homogenization, or encourage an emulsification, temperature control is often needed in the final stages of formulation. Huber has a solution to every application at every temperature.

As standards are developed, quality control will become more common place in the cannabis sector. Huber recirculating chillers, heated baths, and beer aging baths regularly play an integral role in analytical and quality assurance labs across the world.

Summary

HUBER is a technology leader for high precision and responsive temperature control solutions for research and industry. Our product range offers solutions for all temperature applications from -125 °C to +425 °C. The product range includes highly dynamic temperature control systems with cooling capacities of up to 250 kW as well as chillers and heating/cooling circulators for applications in R&D laboratories, pilot plants, and production facilities. Huber has pioneered the technological development in the field of fluid temperature control with several innovative products. A revolution in temperature control technology was the introduction of the Unistat temperature control systems in 1989. 30 years later, Unistats set the pace when it comes to highly dynamic temperature control processes.

Advantages:

• Responsive thermodynamics for fast control behavior for chemical processes.

• Extremely fast heating and cooling rates due to small internal volumes.

• Process stability, predictable and reproducible results at any time for solid research and production.

• Intelligent TAC function continually monitors performance for optimum control.

• Wide range of models covering different temperature ranges with cooling/heating capacities.

• Broad working temperature ranges without liquid change and working life of the HTF.